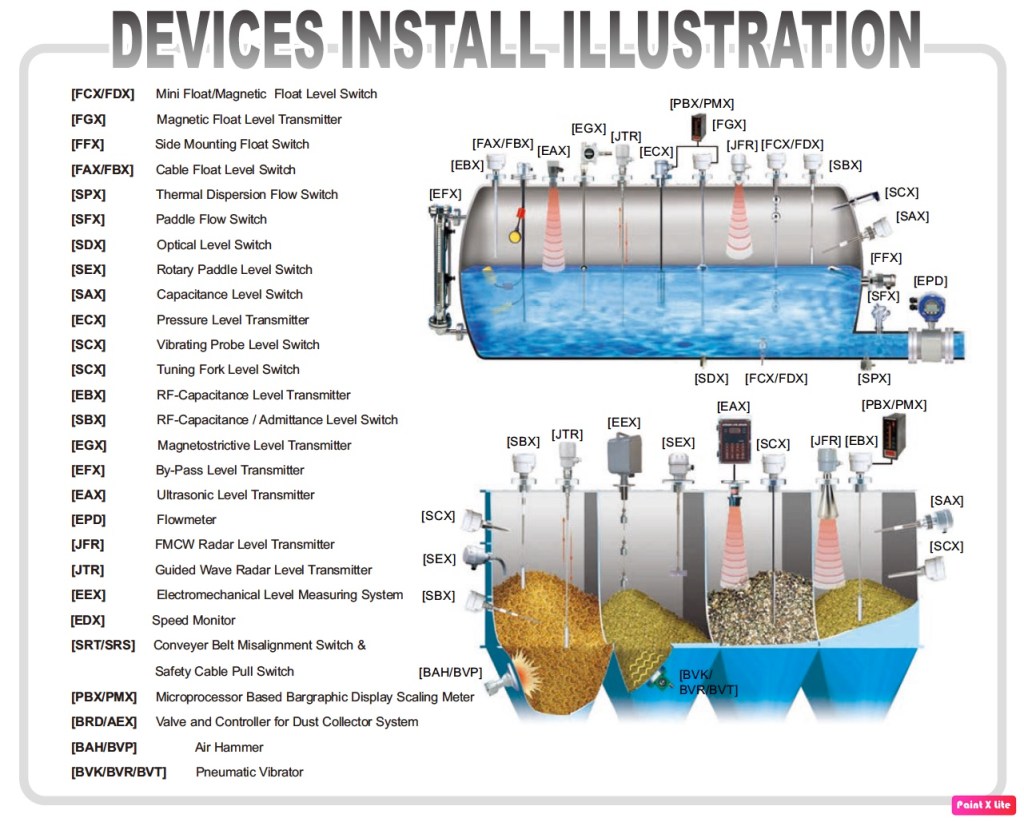

As your organization upgrade to advance process automation sensor integration systems, we work with trusted partner to be part of your automation initiative. In embracing industrial 4.0, WIFI, 4G, IoT and other wireless transmission connection functions to your existing products or systems, we aim to meet customers’ need for the latest technology applications.

Flowmeter

- Electromagnetic / Coriolis mass/ Vortex flowmeters applicable for various fluid detection

- High accuracy & cost effective.

- Easy installation & min. maintenance.

Side Mounting Float Switch

- Max. operating temperature 350C

- Welted parts available with stainless steel and plastic

- Housing available with explosion proof and anti-corrosive

Radar Level Transmitter

- Non-contact measurement

- LCD display and user friendly calibration

- Available for high pressure, high temp, high viscosity and dusty environment

- Intrinsic safety and explosion proof

- Measuring range 0.5m to 40m

- Wireless supported

Optical Level Switch

- NPN, PNP open collector output to energise relay or PLC

- Outer material consists of Polycarbonate, Polysulfone, SUS304/316 for acidity and alkaline applicable in grease, waste water, liquor, alcohol, etc.

- LED status indication

- Application: leakage detection, motor/pump protection

Paddle Wheel Flowmeter

- 128*64 LCM display, convenient operation

- NPN and PNP pulse output

- 4-20mA analog output

- Wide range of voltage supply

- RS485 communication interface, Modbus communication protocol

- Display module can be separated

Thermal Dispersion Flow Switch

- Open collector alarm output

- Measuring range (water): 1~150 cm/s, oil: 3~300 cm/s

- Material: SUS304/ 316, PVDF, PP

- Application: water plant tank, HVAC system, steel marking, petrochemical, food process, pharmaceutical, semiconductor, cooling pipe

Magnetic Float Level Switch

- Custom-made multi-point control, easy installation.

- Max operating temperature 200C for stainless steel

- Application: liquid processing, heat exchanger, hydraulic, power plant, oil, shipbuilding petrochemical industries

By-pass Level Transmitter

- Material SUS316, PVDF, PP, Titanium

- High temperature, up to 400C

- High pressure up to 130 bar

Wireless Module Monitoring System

- End Device: Wireless Communication support for transmitter/switch

- Router: Collect/transmit point-point communication data of each terminal among system structure.

- Coordinator: Enable central control system & MMS to control each wireless device. Retrieve measurement data of each sensor to achieve unlimited measurement purpose

- HubLink: Expand sensor connection by wire/wireless. Max. 4 sets of 4-20mA or RS-485 communication protocol

Ultrasonic Level Transmitter

- Non-contact operation ensures readings will not be affected by material characteristic (e.g. pressure, viscosity, density)

- Liquid measuring range max. 50m, short range 5m available.

- Solid measuring range max.35m, short range 5m available

- Level, distance, flow volume display function selectable

Rotary Paddle Level Switch

- Torsion adjustable for light material

- Temperature up to 200C

- Various power supply selectable

- Application: suitable for chemical, food, mining, plastic, ceramic industries

Pressure Level Transmitter

- Designed for complete submersibility

- Pressure range: 0.1~400 bar

- Output 4-20mA, or 0-10Vdc

- Zero & Span adjustment

Electromechanical Level Measuring System

- Microprocessor based controller

- Standard measuring range of 45m, with maximum of 70m available

- Different types of sensing weights to select from

- Alarm output for sensing probe buried and probe wire broken condition

- Application: ore, clinker, coal, cement, grain, plastic powder, feedstuffs, granule, and any liquid